Product brief description

| Basic Parameters |

Material |

Thickness:0.3-0.8mm

Input width:According to drawing

Effective width:According to drawing

material: GI strips

|

| Power supply |

380V, 50Hz, 3 phase (according to customer request) |

| Capacity of power |

main power: 5.5KW

hydraulic power:3.0KW

Servo motor:2.2KW

|

| Speed |

Forming speed:40m/min |

| Total weight |

Approx.2- 4 tons |

| Dimension |

Approx.(L*W*H) 5.5m*1m*1.2m |

| Stands of rollers |

Approx 10-14 rollers |

| Cut style |

Hydraulic cutter |

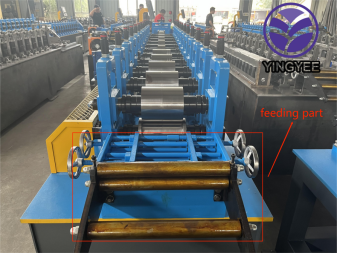

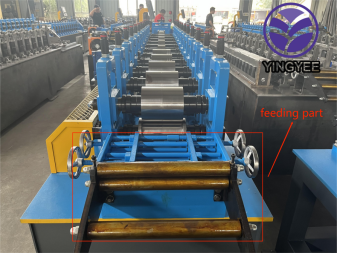

Product details description

3 tons manual decoiler

Feeding guide system

Mainly forming system

Cutting servo motor control without stop

Hydraulic station with cool fan

PLC control and touching screen

Receiving table

Product parameters table

| wall angle roll forming machine |

| 3 tons manual decoiler |

1.3 tonsmanual decoiler

2.Inner diameter of coil: 450-600mm |

| Feeding guide system |

Input width adjustable |

| Mainly forming system |

Matching material: GI strips

Thickness:0.3-0.8mm

Main power:5.5kw, Hydraulic power:3.0kw ,servo motor:2.2kw

Machine structure:Torrist Stand

Forming speed:No stop cutting, 40m/min

Shaft material and diameters:#45 steel and 50mm (Made the steel for cementation)

Roller material:Cr12 with well heat treatment, 58-62

Forming Steps:10-14 steps for forming

Driven:chain drive

K reducer

|

| Cutting servo motor control without stop |

Servo follow cutting,caterpillar sliding with 1.2m guide.

Material of cutter blade:Cr12 mould steel with quenched treatment, HRC 58-62℃

|

| Hydraulic station with cool fan. |

hydraulic power:3.0KW |

| PLC control and touching screen |

PLC control and touching screen(zoncn) |

| Receiving table |

No power collected table |

| Equipment component |

Manual decoiler x1set

Feeding guide system x1set

Mainly forming system x1set

Cutting servo motor control without stop x1set

Hydraulic station with cool fan. x1set

PLC control and touching screen x1set

Receiving table x1set

|

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY