Product brief description

| No. |

Items |

Spec: |

| 1 |

Material |

Thickness:0.8-3.5mm(according to the customer requirement)

Input width:75~285mm(according to the customer requirement)

Inner Diameter of Coils:508mm

Outer Diameter of Coils:Φ1100~Φ1600mm

material: carbon steel ,Low carbon steel

|

| 2 |

Power supply |

6. 380V three-phase electricity 50Hz(according to the customer requirement) |

| 3 |

Capacity of power |

main power:About 600KW |

| 4 |

speed |

90m /min |

| 5 |

Total weight |

Approx.20 tons |

| 6 |

Dimension |

Approx.(L*W*H)for roll forming machine:Approx 23m*2m ( according to the using) |

| 7 |

Cut style |

Fly sawing cutting |

Product details description

Speed:90m /min

Total weight:Approx.20 tons

Capacity of power:main power:About 600KW

Hydraulic Uncoiler ( Double head) :

Shearing & Welding Machine

Horizontal Accumulator

Forming & Sizing Mill:

Scarfing roll stand:

Flying cutting saw

Product parameters table

1 Hydraulic Uncoiler ( Double head)

The uncoiler is designed to support the steel coil and provide production

material for the whole tube mill line.

| Width of strip |

75-240mm |

| Weight of strip |

single coil Max.3 tons, double head total max 6 tons |

| Expansion Type |

Hydraulic Expansion |

| Brake |

Pneumatic brake |

| Work head turning |

Manual turning |

| Width of strip |

75-285mm |

| Strip thickness |

0.8~3.5mm |

| Cutting Type |

Hydraulic Shearing |

| Welding Method |

Argon arc Welding |

| Argon Gas |

Purity more than 99.99% |

| Steel Grade |

σb≤520 MPa σs≤235Mpa |

2 Shearing & Welding Machine

Shearing & Welding Machine is used to cut the irregular ends of the

strips and then connect the two strip ends by argon arc welding, with pneumatic

shearing and automatic welding, working time of 2-3 minutes.

| Width of strip |

75-285mm |

| Strip thickness |

0.8~3.5mm |

| Cutting Type |

Hydraulic Shearing |

| Welding Method |

Argon arc Welding |

| Argon Gas |

Purity more than 99.99% |

| Steel Grade |

σb≤520 MPa σs≤235Mpa |

3 Horizontal Accumulator

To guarantee continuous production, the Accumulator stores strip allowing

time for the operator to use the shear and end welder to connect the strips. The

device is convenient in installation and easy to operated.

| Strip width |

75~240mm |

| Strip thickness |

1.2~3.5mm |

| StoringCapacity |

0m –300m |

| Feeding speed |

Max 120m /min |

| Feeding Motor |

18.5kW |

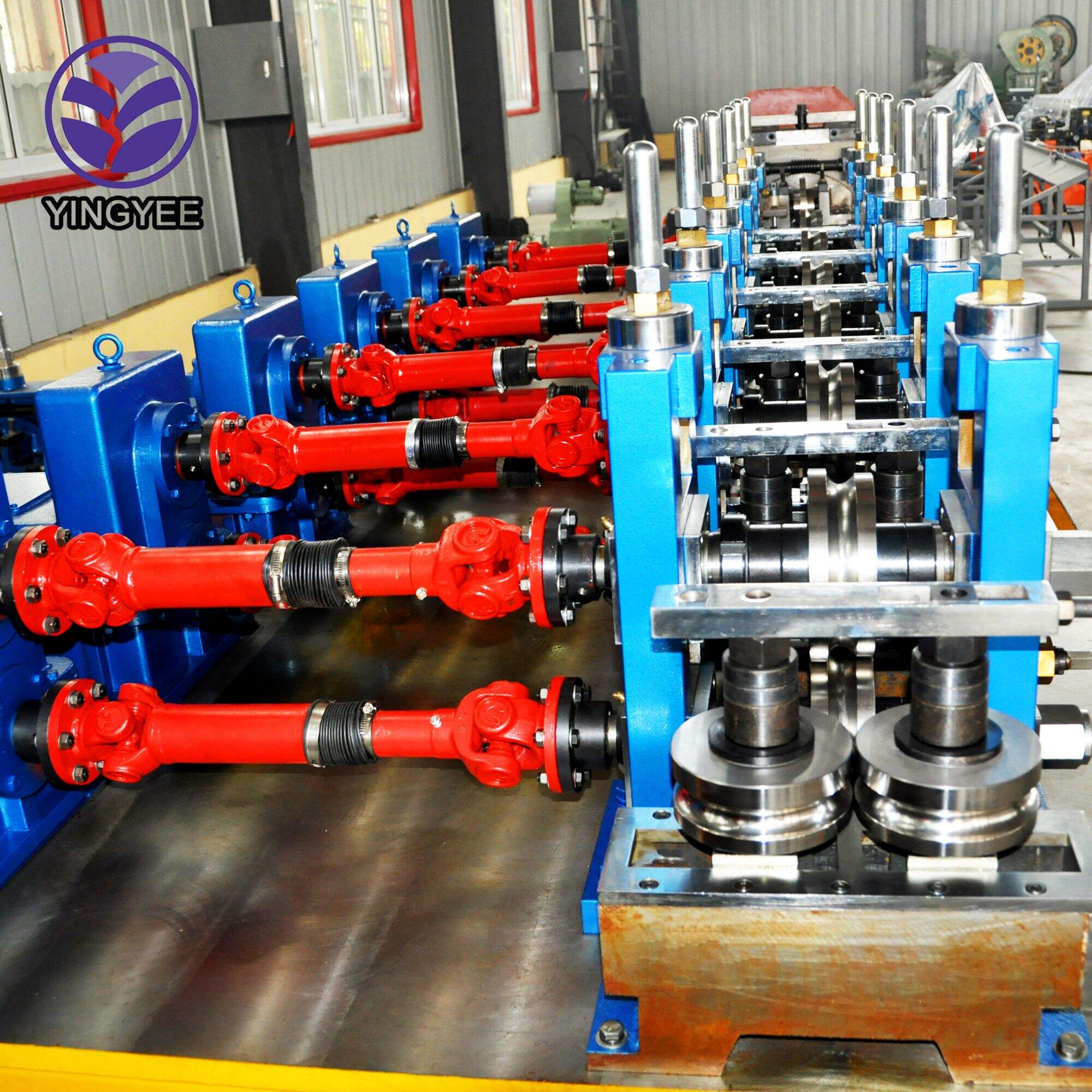

4 Forming & Sizing Mill

Forming & Sizing Mill, forms the steel strip of a certain specification

into tube blank and welds them into rounds with HF current. When the gradually

rolling strip starting from the edge guide to the weld box reaches the HF

welder, the W roll forming mode and induction welding adopted in this mill line

is a proven designs. The two side of the strip are heated to the welding point

and are squeezed together.

Next are removing weld beads, cooling, sizing and roughly straightening.

The horizontal bottom line method is adopted in this mill and double radius

for the rollers.

This section includes the forming mill, welding machine, cooling device and

sizing mill.

Ø Main technical parameters:

Round pipe diameter: Φ 25~Φ90mm

Thickness round pipe : 0.8mm~3.5mm

Square pipe: 20* 20mm~70*70mm

Max. Working Speed: 90m/min

Master motor power: DC185KW

Forming method: Bottom line and “W” forming

Ø Mill stands lay-out:

H stands for Horizontal Stand, V stands for Vertical Stand, T stands for Turk

Head

General layout:Forming 7H8V, sizing 6H6V2T

Feeding---H1---H2---V1---H3---V2---H4---V3---V4---V5---H5---V6---H6---V7---H7---V8--

Guiding --- Squeezing-- Outer de-burring --- Polishing --- Water cooling

---V9---

H8---V10---H9---V11---H10---V12---H11---V13---H12---V14---H13---T1---T2

Ø Forming Mill Parameters

Feeding and leveling device: One set

Horizontal roll stand:

Horizontal roll axle diameter of 80mm, material of 40Cr, whole roll thermal

refining processed, surface high-frequency hardening processed.

Roll stands material cast steel or plate welded, gear slider block of 45

forged steel;

Side off when changing the rollers;

Vertical roll stand:

Vertical roll axle diameter of 50mm, material of 40Cr, whole roll thermal

refining processed, surface HF quenching processed;

Vertical roll base material cast steel or plate welded;

Gear Distribution box:( with Universal Shaft)

Box body: plate welded

Gear material: 20CrMnTi, carburizing and quenching

Seam guide stand:

The roll stand can be adjusted in several directions so that the seam can be

guided into the welding position correctly.

2 roll Weld box( 2 Rolls ) with scarf bead :

This section is used to squeeze the two HF heated edges forging them

together. It has 2 rolls to make the two halves to be properly contoured during

the forging of the two heated edges.

Side Roll axle diameter Φ55mm;Roll shaft material 40Cr;

Scarfing roll stand:

Two scarfing stands to remove the external weld bead; the scarfing tool can

be adjusted horizontally and vertically. crosswise and longitudinally, and with

quick lift function and two holding rolls.

Polishing roll stand:Free drive stand

polish the welding seam after scarfing;

Structure: two passive roll, gantry structure

Roll axle diameter: 80mm, material of 40Cr

Water cooling section:Length ( 2m)

Spraying and submersion at the same time to quickly make the tube cool and

prevent the tube from shaping when sizing.

Sizing Mill

Horizontal Roll Stand:(Refer to that in the forming mill)

Vertical roll Stand:(Refer to that in the forming mill)

Turks Head Stands: 2 sets

Four rolls on each head (stand) can be adjusted in several directions to

straighten the tube

reversely and then deliver a straight tube properly shaped the pipe into the

cutting section straightly.

Roll axle diameter: 50mm, material of 40Cr;

Gear distribution box:(Refer to that in the forming mill)

Master drive system:

DC185KW, with hard face reducer;

All the mill worktables

Transmission shafts one set;

Water piping inside the tube mill

5. Flying cutting saw

Flying cutting saw is used to precisely cut the pipe to length automatically

under the condition that the pipe continuously delivered from the mill at high

speed.

| Diameter of pipe |

Φ25mm~90mm |

| WT of pipe |

0.8-3.5mm |

| Fixed Cutting length |

6m |

| Cutting Accuracy |

0-6mm |

| Saw cutting motor |

30 KW |

| Carriage driving motor |

22 KW |

| Saw blade size |

600mm |

| Cutting Speed |

Max.90m/min |

6. Solid-state High Frequency Welder: 300 KW

Solid state H.F. welder main circuit structure is a typical AC-DC-AC variable

frequency structure. Rectifier adopts 3-phase bridge style thyristor

phase-control rectifier circuit, DC side adopts inductor, capacitor to compose

LC filter which meet the working requirements of voltage type inverter. The

voltage type inverter adopts modularization parallel structure to extend power

supply power, each inverter module is single phase MOSFET bridge style circuit

connected with series resonance tank circuit by H.F. matching transformer. On

one hand, the matching transformer realizes power combination and impedance

matching; on the other hand it realizes electric isolation of load and power

supply. To put effective and swift protection on over-current malfunction of

voltage type inverter, our company introduces special and stable over-current

protection circuit which guarantees safe and stable running of inverter.

Welder include:

Switch rectifier cabinet, inverter output cabinet, water to water cooling

system, central control table, mechanical adjustment device and so on.

DC drive system: Euro 590 speed controller

Forming and sizing mill motor control: Euro control device;

7 Run-out Table

The finished pipes run along the roll table and goes to the bench. Then

simple packing machine collects the pipes into needed shape.

Motor of roll bench: 3Kw , speed adjustable;

8 Tooling:

Material Cr12, hardness HRC58-62; squeezing roll material H13;

Tooling size: 25mm,40mm,90mm

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY