Product brief description

| No. |

Items |

Spec: |

| 1 |

Material |

1. Thickness:0.28-0.5 mm

2. Input width:According to the drawing

3. Material:Galvanized strip coil

|

| 2 |

Power supply |

380V,50Hz, 3Phase |

| 3 |

Capacity of power |

Main power:11kw |

| 4 |

Speed |

8-10m/min |

| 5 |

Total weight |

Approx. About 4Ton |

| 6 |

Dimension |

Approx.(L*W*H)About 4900*1100*1400mm |

| 7 |

Cut style |

Flying sawcutting ,Servo motor, no stop cutting |

Product details description

1. Put the 3 tons manual de-coiler uncoils strip.

Warm box(heaten the material)

Roll-forming Machine

Injection machine

roll forming machine

Punching device

Flying saw cutting

Product parameters table

| Decoiler |

Functional and structural characteristics:

It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand. The uncoiler can bear 3t. It is suitable to process the coiled steel with the inside diameter 508mm .

Feeding the material into the platform |

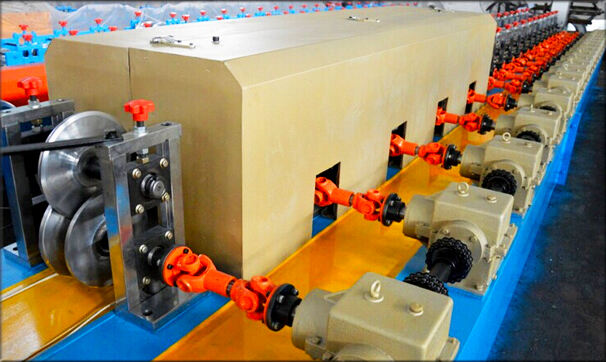

| Roll forming part |

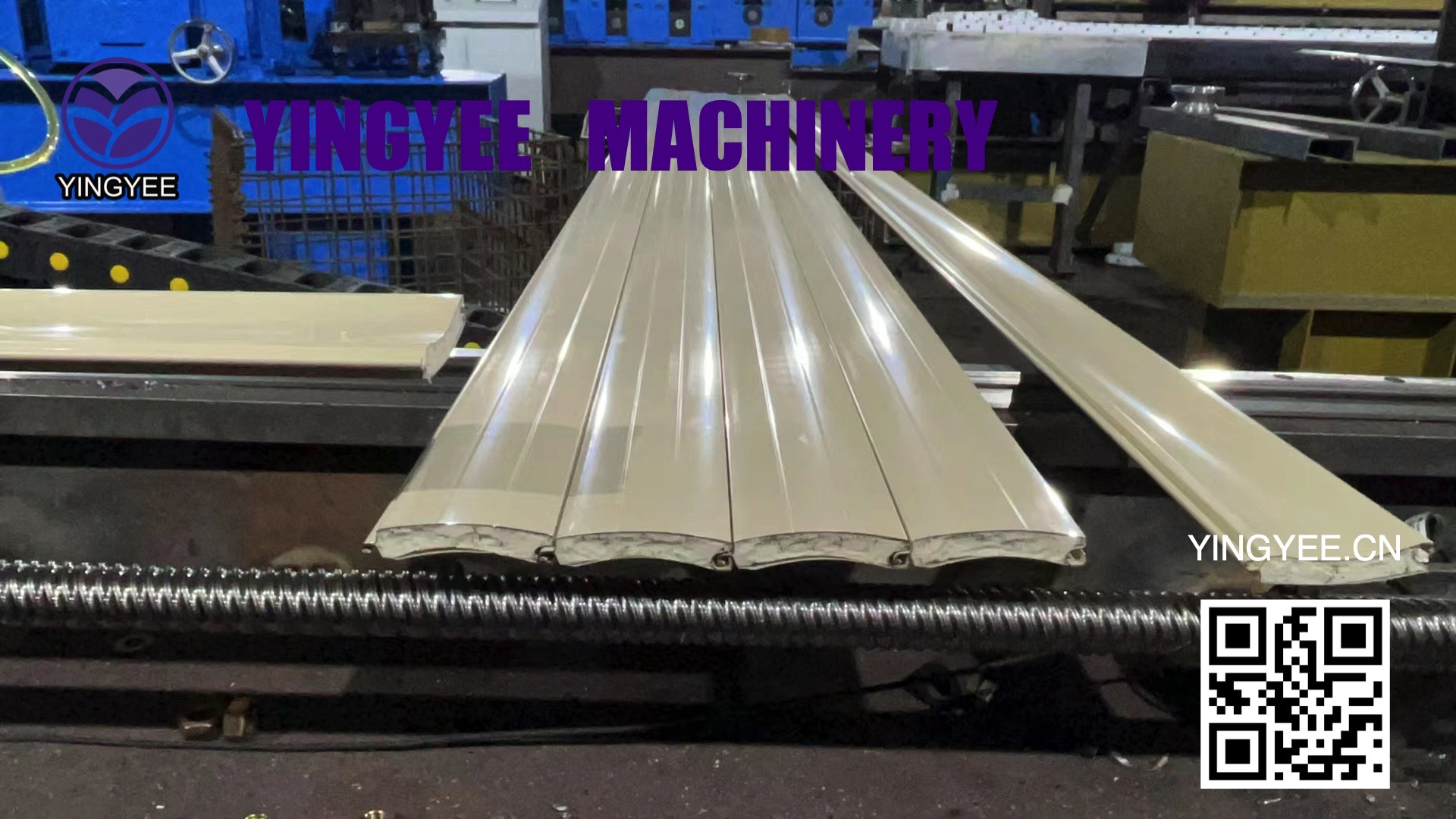

Material type: Aluminum coil plate and colorful galvanize steel

Material thickness:0.28-0.5mm

Material yield strength: ≤G200Mpa

Formingrollers:35-38 rollers

Roller material GCr15: model steel, HRC50-54

Axial diameter: Φ65mm

Main axial material: 45# steel HRB260-280

Driving part:gear box transmission

Frequency conversion decelerating

PLC control: fix length control ±1mm

Main components: CHINT, DELIXI

The precision of roller: less than ±0.5mm

Main roll forming machine motor: 380V, 50HZ, 11kw (or according to your requirements)

Machine basement material: H beam

Working speed:8-10m/min

|

| Heaten box |

Lamp heaten material

Two heaten boxes: before and after injection foam |

| Injection machine |

To make the PU into the products |

| Computer control cabinet : |

(1)Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase

(2)Automatic length measurement

(3)Automatic quantity measurement

(4)Computer used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved

(5)Length inaccuracy can be amended easily

(6) Control panel: Button-type switch and touch screen

(7)Unitof length: millimeter (switched on the control panel)

|

| Cutting |

Pneumatic flying punching machine:

Material of cut: Cr12

Quench: HRC58-62 |

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY