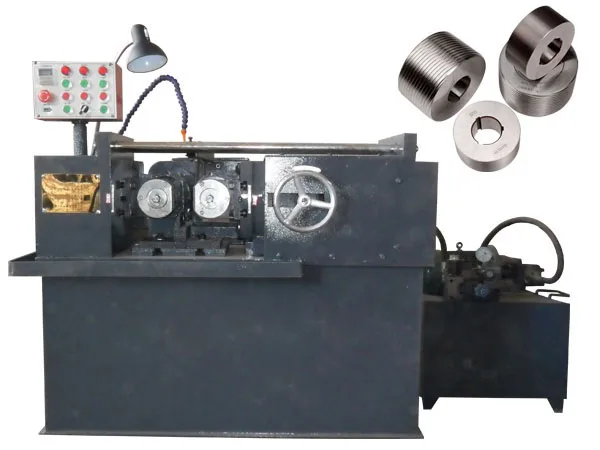

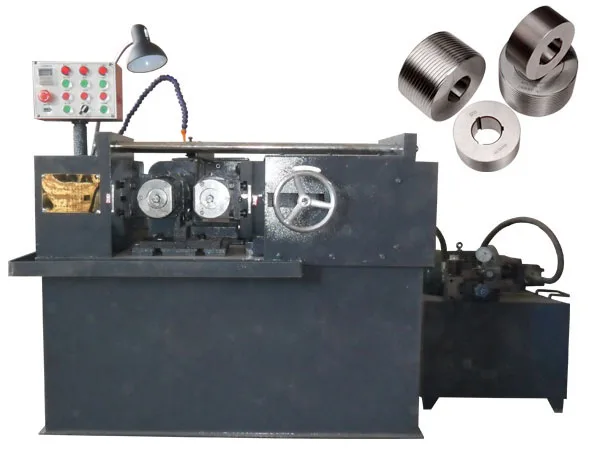

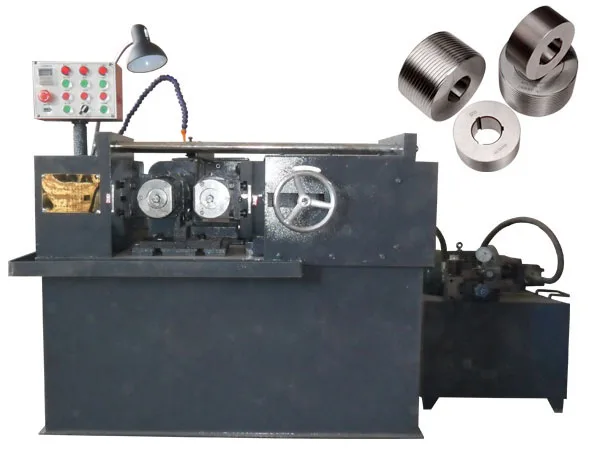

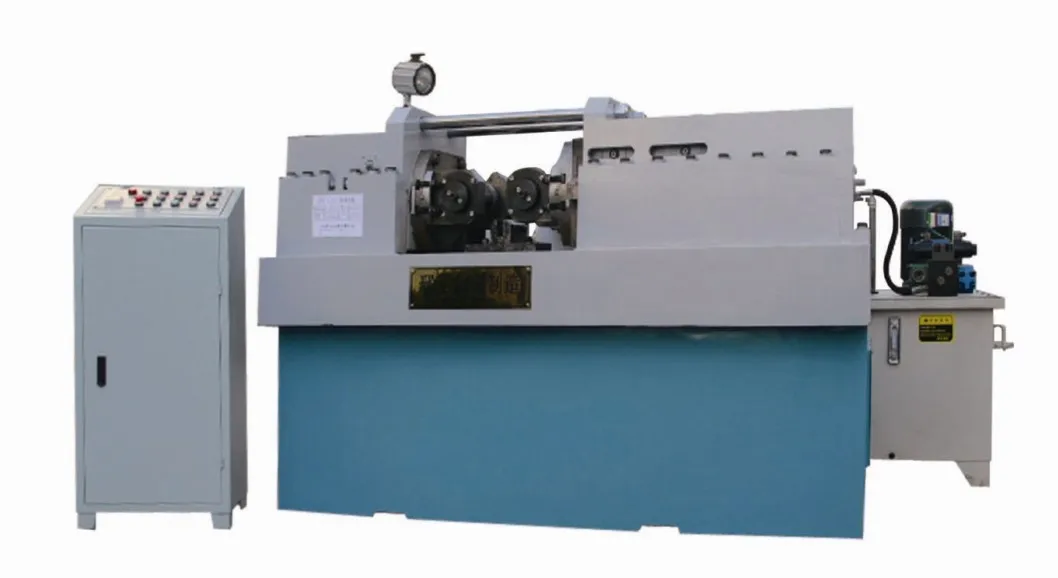

Thread rolling machinery bolts and nuts manufacturing machine screw making

Features:

1. Cam type machine with stable speed

2. Automatic feeder can be designed according to exact product

3. Driving by worm wheel and worm rod

4. It is easy to operate and maintain the machine

5. CE, ISO9001-2008

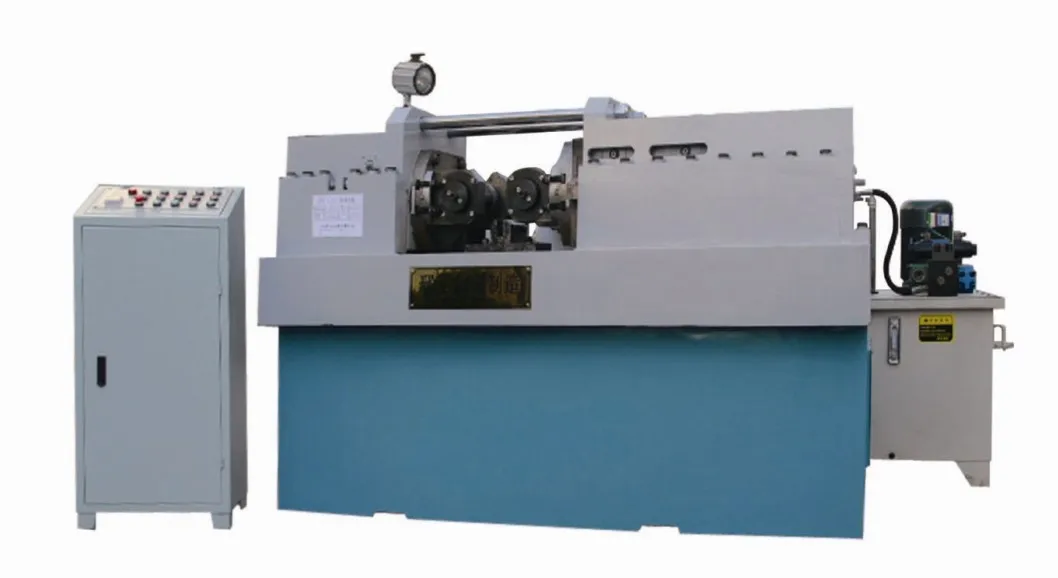

The z28-80 is hydraulic Thread rolling machine, it is supported by strongly structure, manufacture sophisticated,Maintenance easily, mold change quickly.

machining process, also can processed bolts, special bolts, screw rod by change the thread roller

Technical Parameters

|

Pressure of Roller max.

|

150KN

|

Rotary Speed of Main Shaft

|

36,47,60,78(r/min)

|

|

Working Dia

|

φ6-φ42mm

|

Feed Speed of Movable shaft

|

5mm/s

|

|

OD of Roller

|

φ120-φ170mm

|

Main Power

|

4kw

|

|

BD of Roller

|

φ54mm

|

Hydraulic Power

|

2.2kw

|

|

Roller Width max

|

100mm

|

Weight

|

1700kg

|

|

Dip Angle of Main Shaft

|

±5°

|

Size

|

1480×1330×1440mm

|

|

Center Distance of Main shaft

|

120-240mm

|

Thread Length

|

(no limits)

|

Packaging & Shipping

Safe package by tight leak and well wooden package for LCL shipping.

Famous shipping compnay as our partner,

Delivery in time,

Full insurance.

Company Information

Shijiazhuang Yingyee Import&Export Co., Ltd.

YINGYEE is the manufacturer specialized in various cold forming machineries and automatic production lines. We have a wonderful team with highly technology and excellent sales, which offer professional products and related service. We paid attention to quantity and after service, got great feedback and honor from all the clients. We have a great team for after service. We have sent several patch after service team to oversea to finish the products installation and adjustment.

Our products were sold to more than 20 countries already. Also included US and Germany.

Main product :

- Roof roll forming machine

-

Roller shutter door roll forming machine

- C and Z purlin roll forming machine

- Downpipe roll forming machine

-

Light keel roll forming machine

- Guardrail roll forming machine

- Storage roll forming machine

- Cable tray roll forming machine

-

Shearing machine

- Hydraulic decoiler

- Bending machine

- slitting machine

FAQ

F&Q

Training and Installation

1 We offer installation service local in paid, reasonable charge.

2 QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service

-

Match the technology standard, ISO producing certification

-

CE certification

-

12 months warranty since the delivery. Board.

Our advantage:

-

Short delivery period.

-

Effective communication

-

Interface customized.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY