aluminium steel roller shutter machine with PU foam

The shutter slat roll forming machine is fully automatic and it is easy to operate to form shutter slats. The shutter slat roll forming machine consists of one decoiler, sheet guiding equipment, roll forming section, cutter, supporter, hydraulic system and control system.

Machine Configuration:

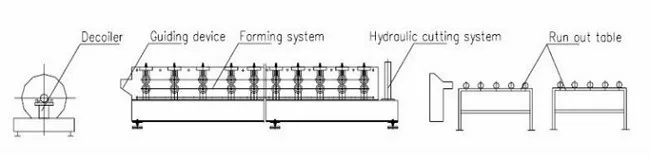

Decoiler, Feeding Applicator, Roll Forming Unit, Straightening Unit, Computer Control System, Hydraulic Cutting, Output Table

Working Flow:

Decoiler—Feeding Applicator—Roll Forming Unit—Computer Contol System—Hydraulic Cutting—Output Table

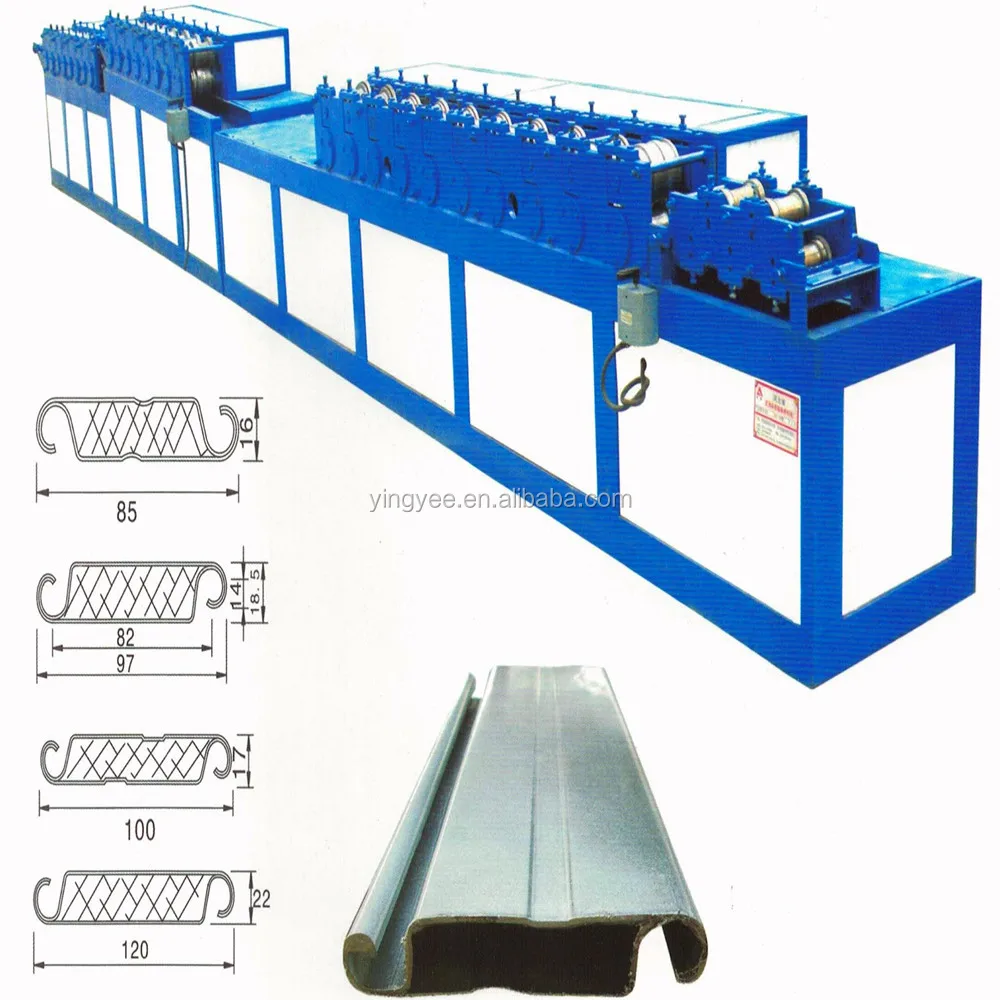

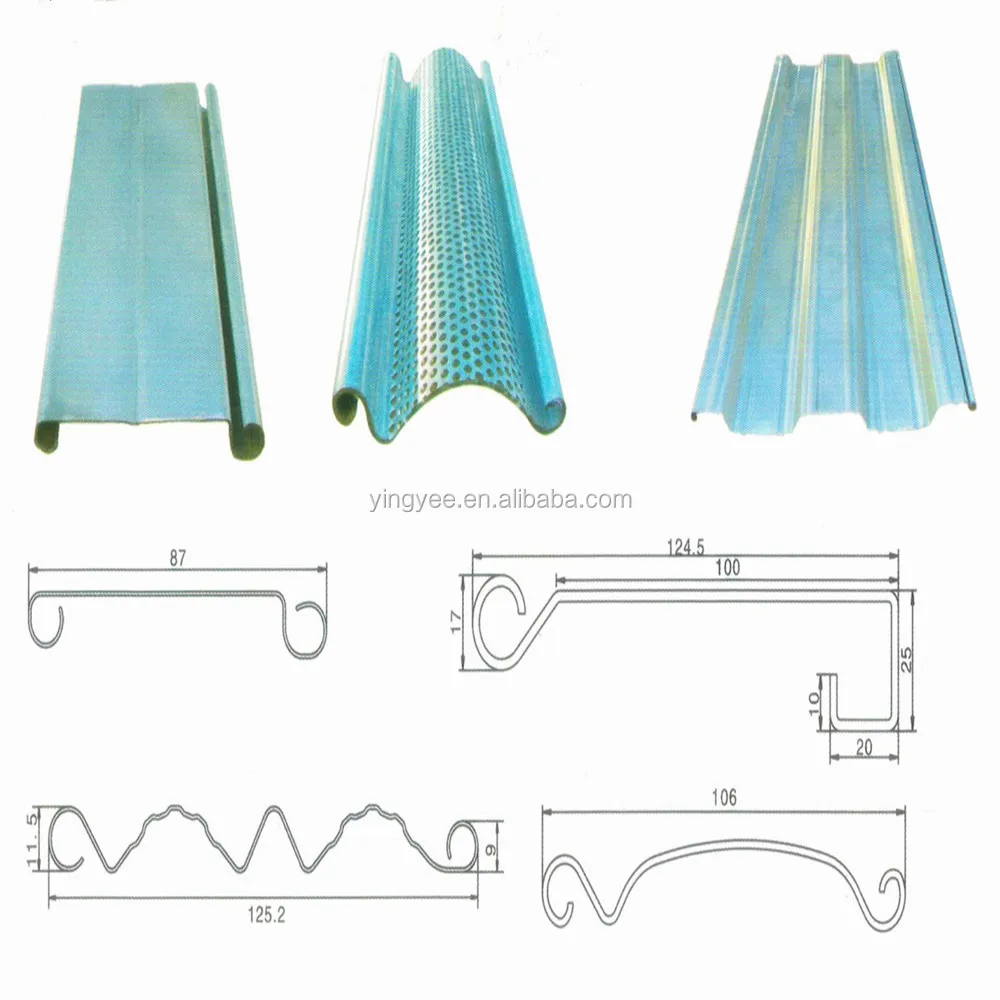

Product Description

Technical parameters:

1. Matching material: color plate

2. Material thickness range: 0.3mm-1.0mm

3. Main motor power: 5.5kw

4. Forming speed: 8-12m/min

5. Hydraulic power: 3.0kw

6. Quantity of stands: about 16

7. Shaft Material and diameter: 70mm, material is 45# forge steel

8.Material Of the stations: A3 steel

9.Tolerance: 3m+/-1.0mm

10.Way Of Drive: 1.0 inch single chain driving

11. Controlling system: PLC system

12. Voltage: 380V/ 3phase/ 50 Hz

14.Size of the roll forming machine: about 9m*1.0m*1.5

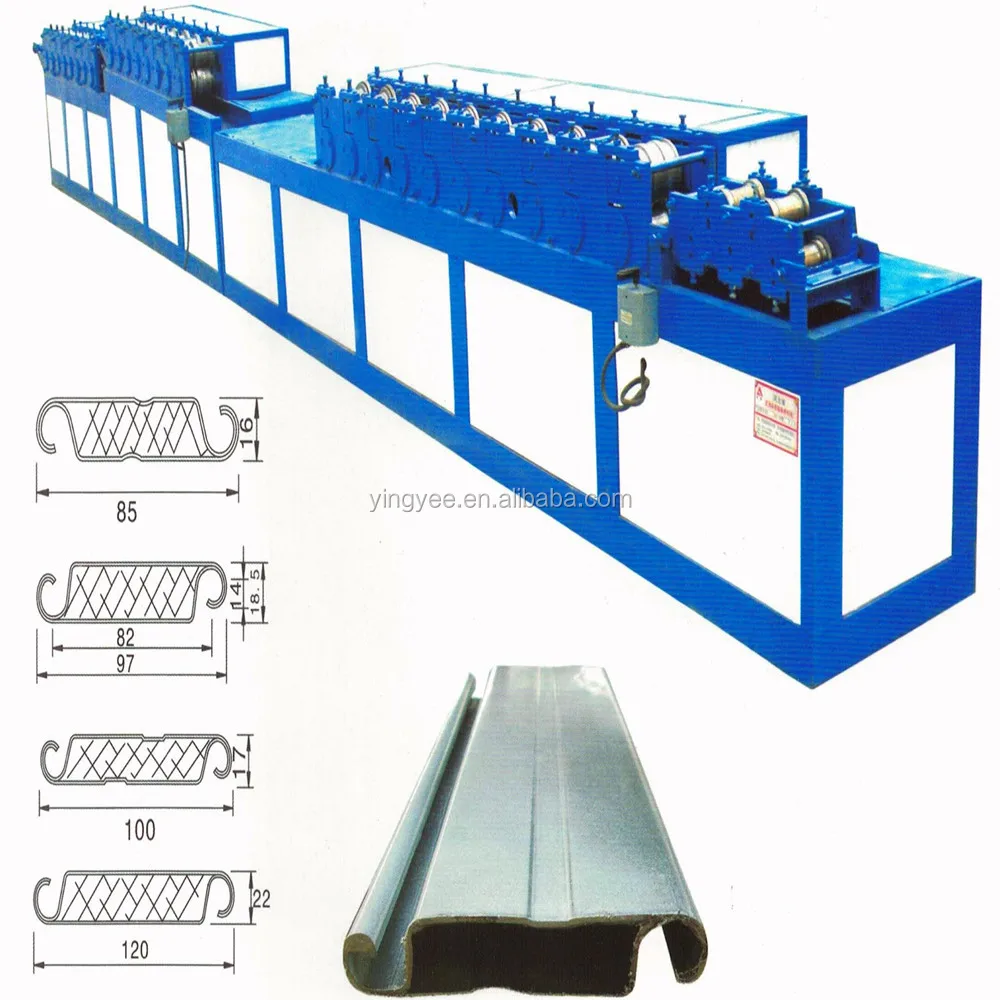

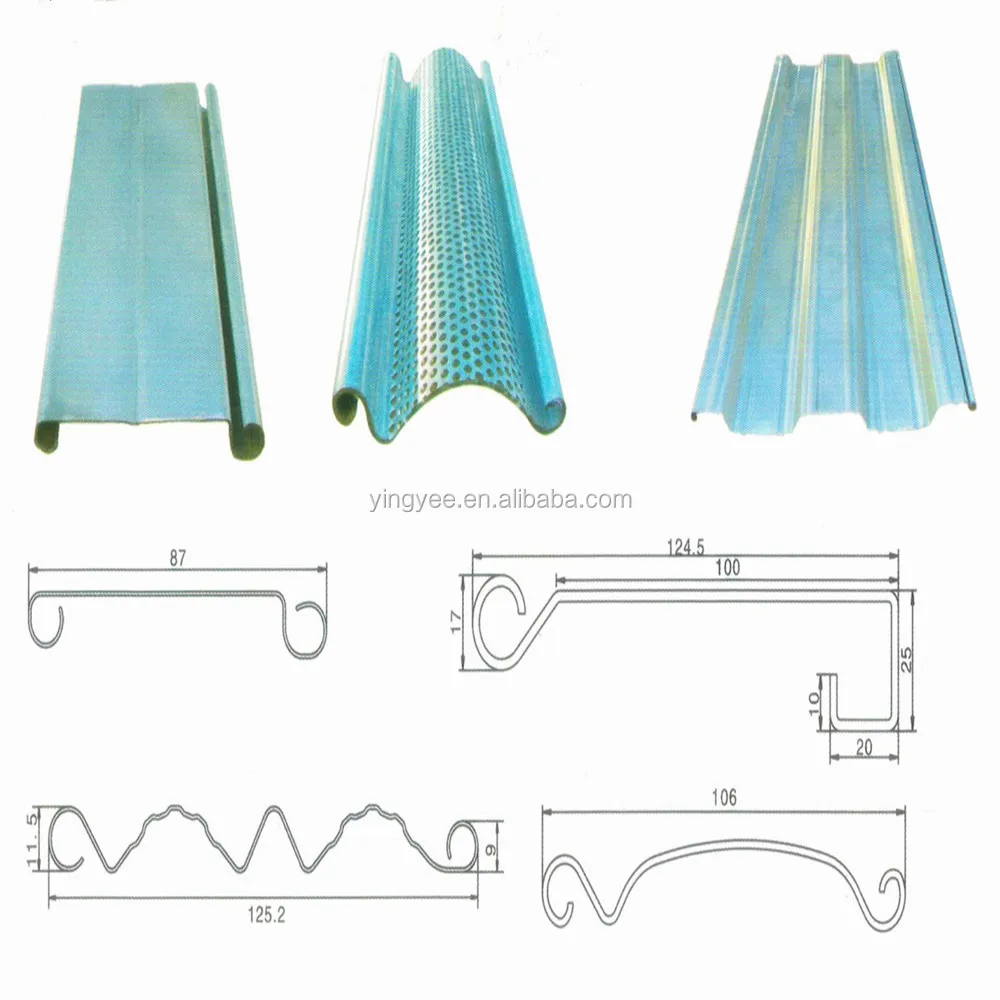

Pictures of machine:

We can design kinds of roll forming machine according to your specific panel profile.

Packaging & Shipping

Main machine is nude, the computer box is packed by plastic film.

Company Information

Shijiazhuang Yingyee Import&Export Co., Ltd.

YINGYEE is the manufacturer specialized in various cold forming machineries and automatic production lines. We have a wonderful team with highly technology and excellent sales, which offer professional products and related service. We paid attention to quantity and after service, got great feedback and honor fromall the clients. We have a great team for after service. We have sent several patch after service team to oversea to finish the products installation and adjustment.

Our products were sold to more than 20 countries already. Also included US and Germany.

Main product :

- Roof roll forming machine

- Roller shutter door roll forming machine

- C and Z purlin roll forming machine

- Downpipe roll forming machine

- Light keel roll forming machine

- Shearing machine

- Hydraulic decoiler

- Bending machine

- Slitting machine

FAQ

Training and Installation :

1 We offer installation service local in paid, reasonable charge.

2 QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service:

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period.

2. Effective communication

3. Interface customized.

Contact us

Welcome to contact us , we are sure you will get good machine quality and best service. Hope to cooperate with you! customized roller shutter roll forming machine

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY