Brevis descriptio producti

| Non. |

Items |

Spec |

| 1 |

Armarium |

1. Crassitudo: Max 0.8mm

2. Profunditas: 200/300mm

3. Largitudo:250-400mm, altitudo:300-600mm

4. Materialis:GI volubilia

|

| 2 |

Potentiae copia |

380V, 50Hz, 3phase |

| 3 |

Capacitas potentiae |

Vis principalis: 7.5kw |

| 4 |

Totalis Pondus |

Circa 9 Tonnarum |

| 5 |

Dimensio |

Circa (L*W*H) 23×3×2m |

| 6 |

Stantes rotae |

Circa 14 gradus rotulus |

| 7 |

Genus praecisionis |

Systema automatum plicandi et secandi |

Product Details description

1. Decoiler sustinet ferrum spira pro explicando.

2. Fasciculus ferri transgit per machinam equalizantem. Facit fasciculum ferrum planius.

3. Fasciculus ferrum planus intrat (alimentatio servomotore) instrumentum perforandi. Potest perficere productionem foraminum quattuor angulorum cacabatis, foramen aeris, et foramina cardinis.

4. In parte formandi, Fasciculus ferrum paulatim plicatur et formatur secundum descriptas imagines.

5. Instrumentum flectendi flectit productum ut formet claustrum. Instrumentum flectendi flectit productum ut formet claustrum. Ter flectitur ad praecidendum.

Product parametri mensa

| 3 tonsmanual decoiler |

Diametrum internum spire ferreae: φ500mm; crassitudo materialis est max 0.8mm

Pondus portandum: ≤3T

Altum centri rotuli: 650mm

Forma sustinentia: Tensio interna

|

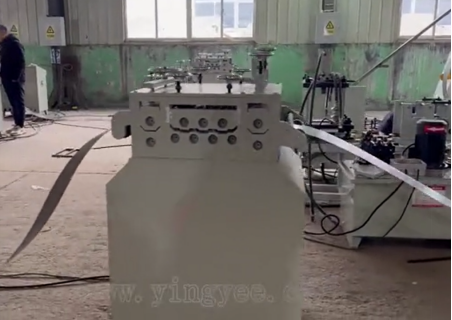

| Machina trahendi et aequilibrandi |

Tractio volventium aequalitas Aequalitas crassitiei: Max 0.8mm Vis: 2.2kw |

| NCF-400 Servo Alimentator |

Servoalimentatiocontrol,Multiplex alimentatio Motor servo: INVT Praecisio alimentationis:± 0.1mm/tempus |

| Systema perforandi |

Constat ex machina quinque-cylindrica hydraulica perforatoria; Machina prima perforatoria: Completa foramina perforata et trahendo (genus incrementale) Machina secunda perforatoria: Completa frontem caecorum Machina tertia perforatoria: Completa dorsum caecorum Machina quarta perforatoria cantilever: Completa bina praecisa angulorum anteriores et cardinem corporis tabularii Machina quinta perforatoria cantilever: Completa bina praecisa angulorum posteriorum corporis tabularii (Machina quinta perforatoria cantilever sita est opposita machina quarta perforatoria cantilever) |

| Faciendum ex formis |

1 coniunctio perforat foramina forma

2 coniunctiones formarum pro anteriori et posteriori obliteratione

1 coniunctio anguli prioris sectandi et cardinis combinatio formae

1 coniunctio posterioris anguli sectandi combinatio forma Materialis formae: SKD11

|

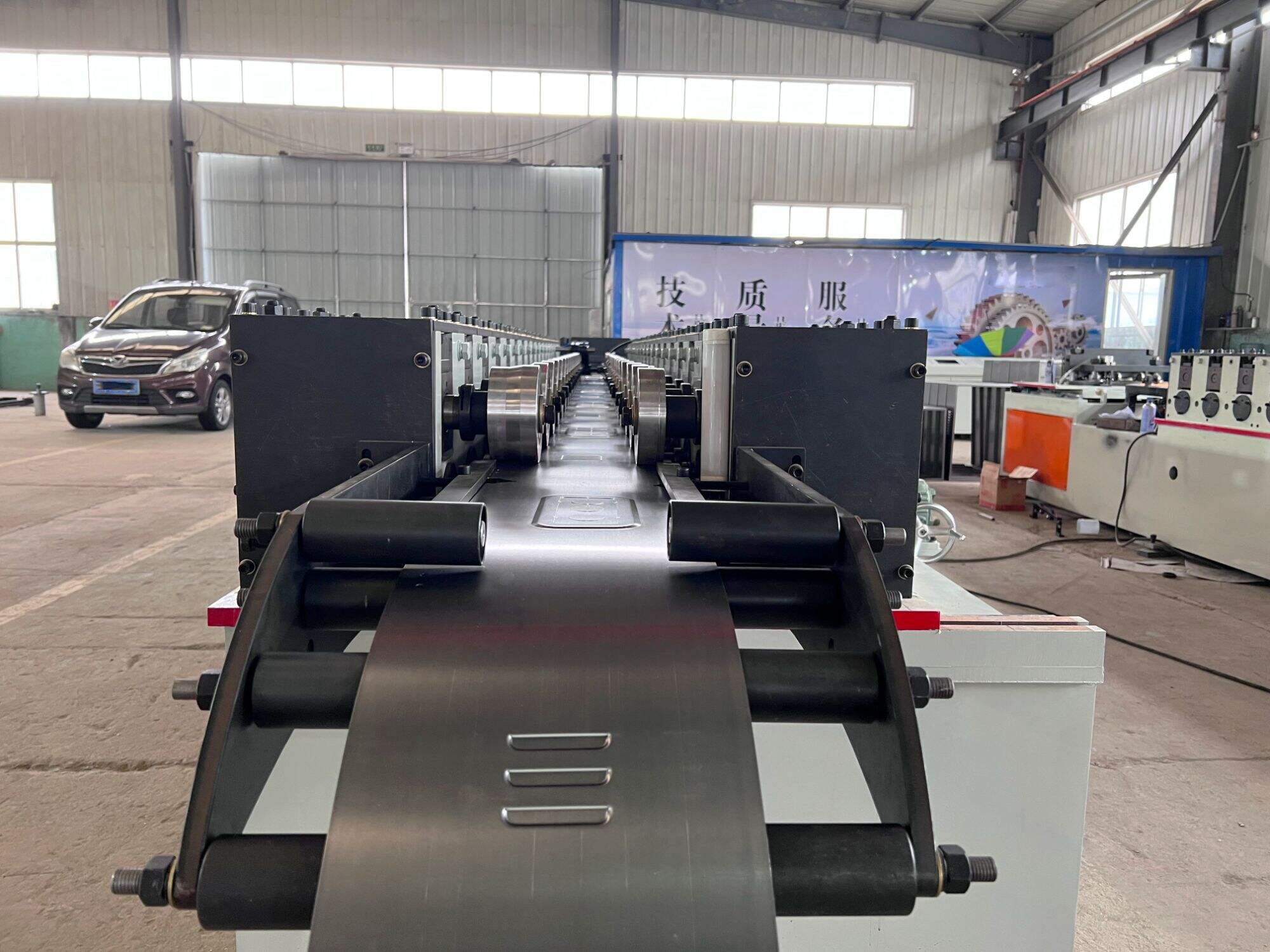

| Machina formandi volutas |

Cantilever roll forming machine: Rapid depth adjustment Including door depth: 200/250/300mm Material thickness: Max 0.8mm Front waterstop size: 20mm Forming steps: About 14 steps Forming machine shaft: 45mm The roller is forged with Cr12 and CNC processed after overall quenching, with a hardness of up to HRC58-62° |

| Systema automatum plicandi et secandi |

Forma: Combinatio gas et liquidum Minimum 300 * 250 Maximum 1000 * 1200 Secare/flectere: Combinatio integrata Materia gladii: SKD11 Flectere: Automaticum flectendum Potentia: 3KW |

| Systema controlis electrici |

Mitsubishi PLC, Interface hominis et machinae, faciens interactionem inter homines et PLC |

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY