Brève description du produit

| Matériau |

Épaisseur : 2 mm (selon le dessin)

Largeur d'entrée : Selon le dessin

Largeur effective : Selon le dessin

matériau : Bandes GI

|

| Alimentation |

380V, 50Hz, 3 phases (selon la demande du client) |

| Capacité de puissance |

puissance principale : 15KW*2+11KW pour machine combinée

Puissance hydraulique : 11kw*2

|

| Vitesse |

Vitesse de formation : moins de 10 m/min |

| Poids total |

Environ 15 tonnes |

| Dimension |

Environ (L*L*H) 26m*1.8m*3.5m |

| Nombre de stands de rouleaux |

13 rouleaux |

| Style de coupe |

Coupeuse hydraulique |

Détails du produit Description

Débobineur hydraulique de 5 tonnes :

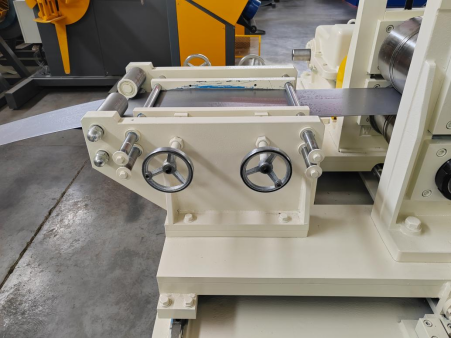

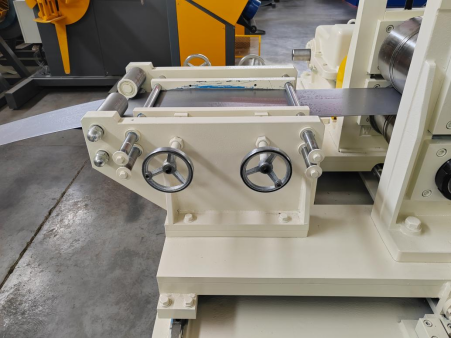

Guide d'alimentation :

Matériau d'alimentation ajustable

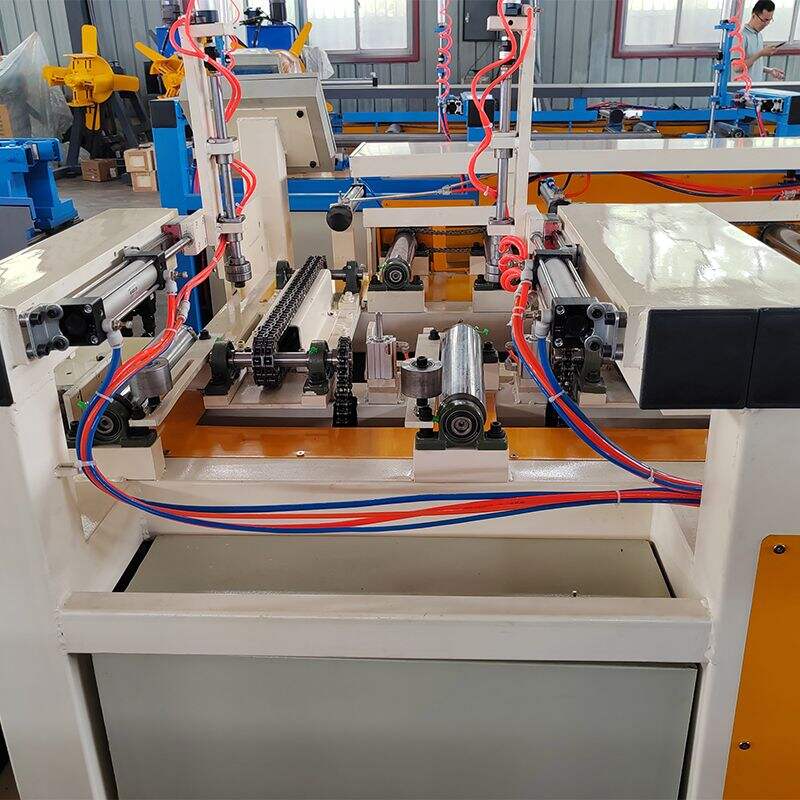

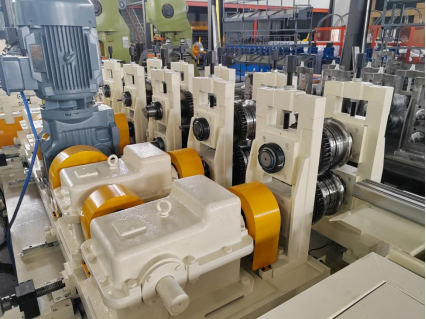

Partie de formage à rouleaux :

Matériau correspondant : CRC, bandes galvanisées.

Épaisseur : 2 mm (selon le dessin)

Puissance principale : 15KW*2

Vitesse de formation : moins de 10 m/min

Étapes des rouleaux : 13 étapes (selon le dessin)

Matériau de l'arbre : acier 45 #

Diamètre de l'arbre : 70 mm

Matériau des rouleaux : CR12

Structure de la machine : structure Torrist

Mode de fonctionnement : par boîte de vitesses

Méthode d'ajustement de la taille : Automatique, contrôle PLC

Ciseau : Coupe hydraulique

Matériau de la lame de ciseau : Acier au chrome Cr12 avec traitement trempé 58-62℃

Tolérance : 3m±1,5mm

Tension : 380V / 3 phases / 60 Hz (ou sur mesure) ;

Ciseau hydraulique :

Matériau de la lame de coupe : acier moule Cr12 traité par trempe, HRC 58-62°C

Table de convoyage :

Système de transfert et de pliage automatique

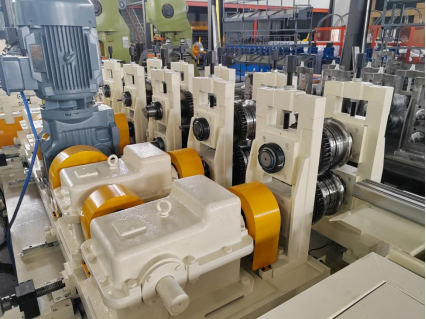

Machine combinée :

Supports de rouleaux : 5 supports (structure Torrist)

Propulsé par une boîte de vitesses

Puissance du moteur principal : 11 kW

Matériau des rouleaux : Cr12

Diamètre de l'arbre : 75 mm

Méthode de fonctionnement : alimentation automatique

Contrôle : contrôlé automatiquement

Table de collecte :

Table de réception hydraulique automatique

PLC:

Contrôle PLC et écran tactile (zoncn)

Tension, Fréquence, Phase : 380 V / 3 phases / 60 Hz (ou sur mesure)

Mesure automatique de la longueur :

Mesure automatique de la quantité

Ordinateur utilisé pour contrôler la longueur et la quantité. La machine coupe automatiquement à la longueur souhaitée et s'arrête lorsque la quantité requise est atteinte.

L'erreur de longueur peut être facilement corrigée.

Tableau de commande : interrupteur à boutons et écran tactile

Unité de longueur : millimètre (commuté sur le tableau de commande)

Station hydraulique :

Table des paramètres du produit

| Débobineur hydraulique de 5 tonnes |

Désbobineur hydraulique de 5 tonnes

Diamètre intérieur de la bobine : 450-600 mm

|

| Système de guidage d'alimentation |

Matériau d'alimentation ajustable |

| machine de formage de rouleaux |

Matériau correspondant : Bandes galvanisées.

Épaisseur : 2 mm (selon le dessin)

Puissance principale : 15KW*2

Vitesse de formation : moins de 10 m/min

Étapes du rouleau : 13 étapes (selon le dessin)

Matériau de l'arbre : acier 45 #

Diamètre de l'arbre : 70 mm

Matériau des rouleaux : CR12

Structure de la machine : structure Torrist

Mode de transmission : par chaîne

Méthode d'ajustement de taille : Automatique, contrôle PLC

Lame : Coupe hydraulique

Matériau de la lame de ciseau : Acier au chrome Cr12 avec traitement trempé 58-62℃

Tolérance : 3m ± 1,5mm Tension : 380V / 3 phases / 60 Hz (ou sur mesure);

|

| Table convoyeuse |

Système de transfert et de pliage automatique |

| Machine combinée |

Blocs de rouleaux : 5 blocs (structure Torrist)

Propulsé par une boîte de vitesses

Puissance du moteur principal : 11 kW

Matériau des rouleaux : Cr12

Diamètre de l'arbre : 75 mm

Méthode de fonctionnement : alimentation automatique

Contrôle : contrôlé par automatisme

|

| PLC |

Contrôle PLC et écran tactile (zoncn)

Tension, Fréquence, Phase : 380 V / 3 phases / 60 Hz (ou sur mesure)

Mesure automatique de la longueur :

Mesure automatique de la quantité

Ordinateur utilisé pour contrôler la longueur et la quantité. La machine coupe automatiquement à la longueur souhaitée et s'arrête lorsque la quantité requise est atteinte.

L'erreur de longueur peut être facilement corrigée.

Tableau de commande : interrupteur à boutons et écran tactile

Unité de longueur : millimètre (commuté sur le tableau de commande)

|

| Table de collecte |

Table de réception hydraulique automatique |

| Station hydraulique |

Station hydraulique avec réservoir d'huile

Puissance hydraulique : 11kw*2

|

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY