Product brief description

| No. |

Items |

Spec |

| 1 |

Cabinet |

1. Thickness: Max 0.8mm

2. Depth: 200/300mm

3. Width:250-400mm, height:300-600mm

4. Material:GI coils

|

| 2 |

Power supply |

380V, 50Hz, 3phase |

| 3 |

Capacity of power |

Main power:7.5KW |

| 4 |

Total weight |

Approx. About 9Tons |

| 5 |

Dimension |

Approx.(L*W*H) About23×3×2m |

| 6 |

Stands of rollers |

About 14 steps roller |

| 7 |

Cut style |

Automatic folding and cutting system |

Product details description

1.Decoiler support steel coil for uncoiling.

2. The steel coil passes through the leveling machine.It makes the steel coil

flatter.

3. The flat steel coil enters(servo feeding) the punching device.It can

complete the production of the four corner holes of the box, Air vent, and hinge

holes.

4. In the forming part, The steel coil is gradually folded and shaped

according to the designed drawings.

5. The bending device bends the product to form a frame.The bending device

bends the product to form a frame. It is bent 3 times for cutting.

Product parameters table

| 3 tonsmanual decoiler |

Inner diameter ofsteel coil: φ500mm; material thicknessis max 0.8mm

Carrying weight: ≤3T

Spindle center height: 650mm

Support form:Inner tension

|

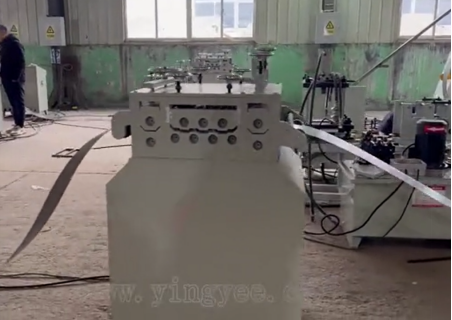

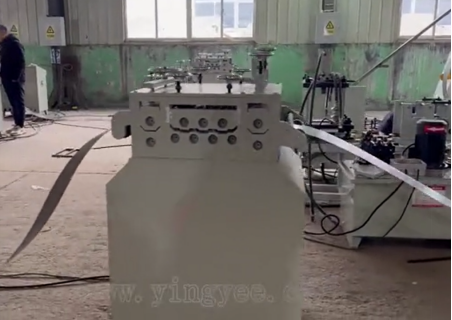

| Traction and Leveling machine |

Roller traction leveling

Leveling thickness: Max 0.8mm

Power: 2.2kw |

| NCF-400 Servo Feeder |

Servofeedingcontrol,Multi-stage feeding

Servo motor: INVT

Feeding accuracy:± 0.1mm/time |

| Punching system |

Composed of a 5-cylinder hydraulicpunching machine;

No.1punching machine:Complete tapping and stretching threading holes (incremental type)

No.2Punchingmachine: Completethe front blinds

No.3Punchingmachine: Complete theback blinds

No.4 cantileverpunching machine:Complete double front corner cutting and hinge of the box body

No. 5 cantileverpunching machine: Complete double rear corner cutting of the box body

(The 5th cantileverpunching machine is located opposite the 4th cantileverpunching machine) |

| Punching moulds |

1 set knock holes mold

2 sets molds for front and back blinds

1 set front corner cutting and hinge combination mold

1 set rear corner cutting combination mold

Mold material: SKD11

|

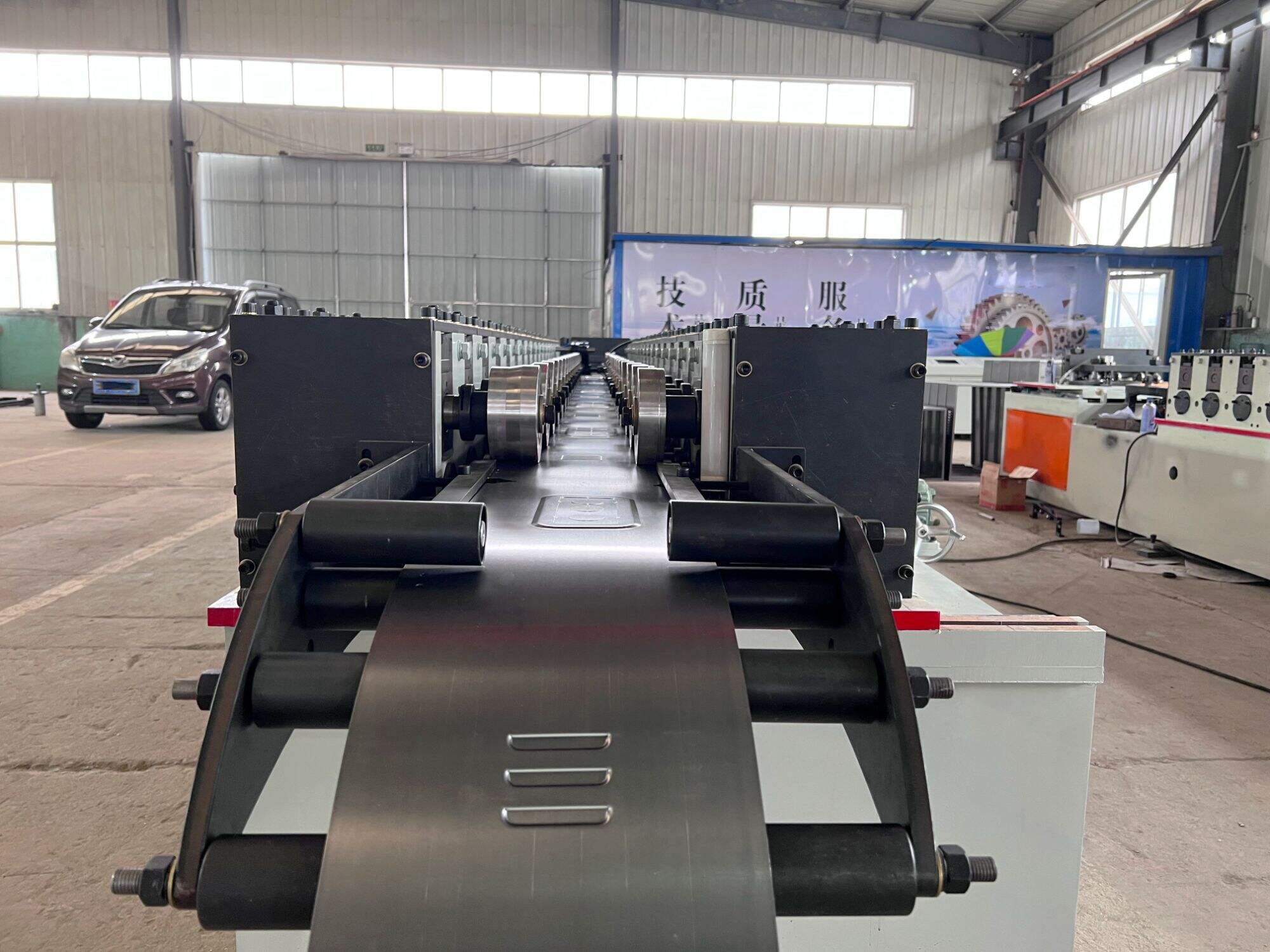

| Roll forming machine |

Cantilever roll forming machine:Rapid depth adjustment

Including door depth: 200/250/300mm

Material thickness: Max 0.8mm

Front waterstop size: 20mm

Formingsteps: About 14steps

Forming machine shaft:45mm

The roller is forged with Cr12 and CNC processed after overall quenching, with a hardness of up to HRC58-62° |

| Automatic folding and cutting system |

Form: The combination of gas and liquid combination

Minimum 300 * 250

Maximum1000 * 1200

Cutting/folding: Combination integrated

Blade material: SKD11

Folding: Automatic folding

Power: 3KW |

| Electrical control system |

Mitsubishi PLC,

Human machine interface, enabling interaction between humans and PLC |

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY