Product brief description

| No. |

Items |

Spec: |

| 1 |

Material |

Thickness:0.3-0.8mm

Input width:according to the drawing

Material:GI/PPGI

|

| 2 |

Power supply |

380V, 50Hz, 3 phase |

| 3 |

Capacity of power |

Main motor power:7.5kw

Hydraulic station:4kw

|

| 4 |

Speed |

Forming speed:about 0-15m/min |

| 5 |

Total weight |

Approx10Ton |

| 6 |

Dimension |

Approx.(L*W*H) About10m*1.5m*1.5m |

| 7 |

Stands of rollers |

18-20rollers(according to the drawing) |

| 8 |

Cut style |

Hydraulic cutter |

Product details description

Decoiler:

1. Max width of raw material:As customer’s requirements

2. Capacity:5000kgs

3. Inner diameter of coil:450-600mm

Feeding guide:

Feeding material with adjustable

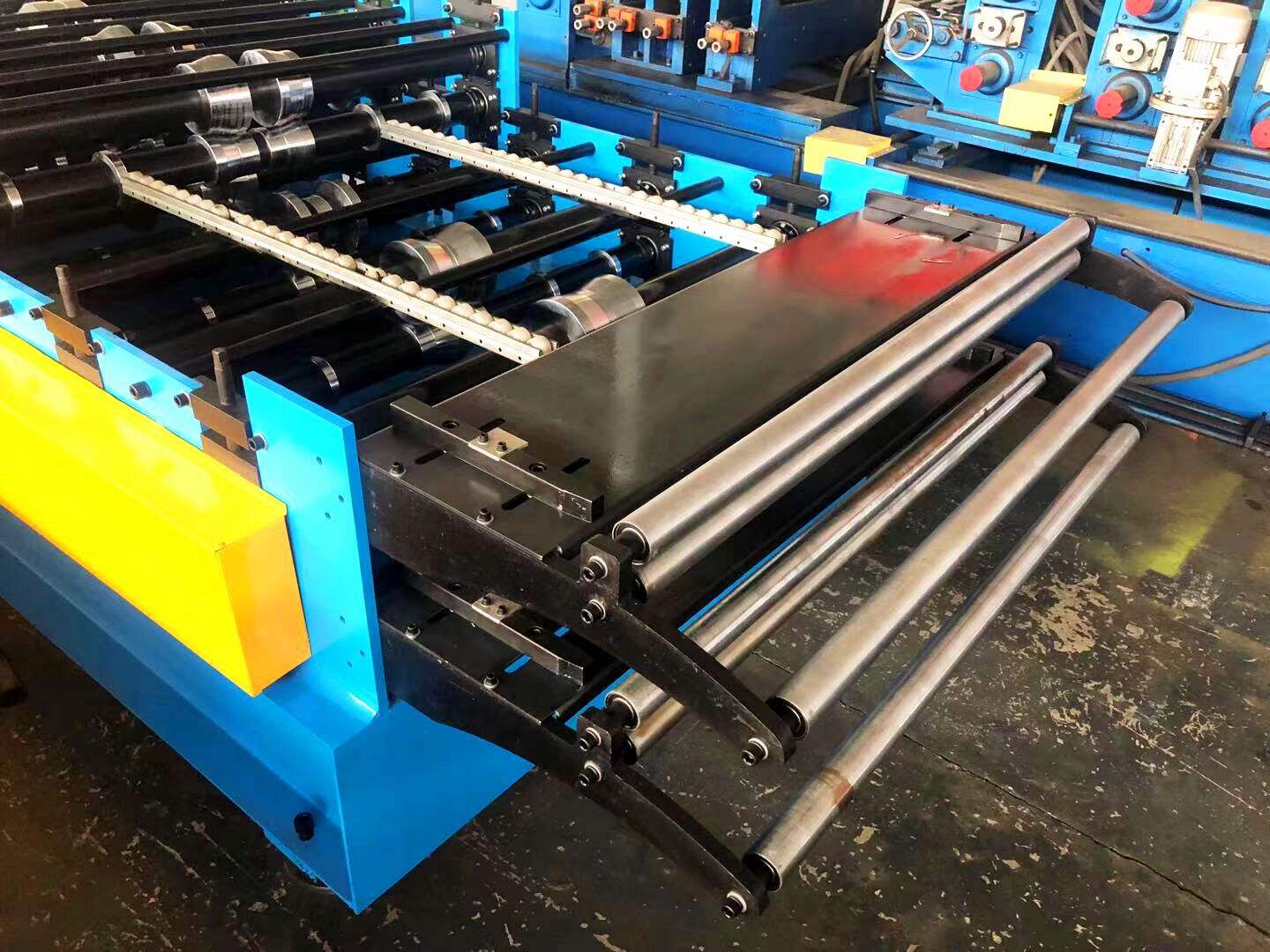

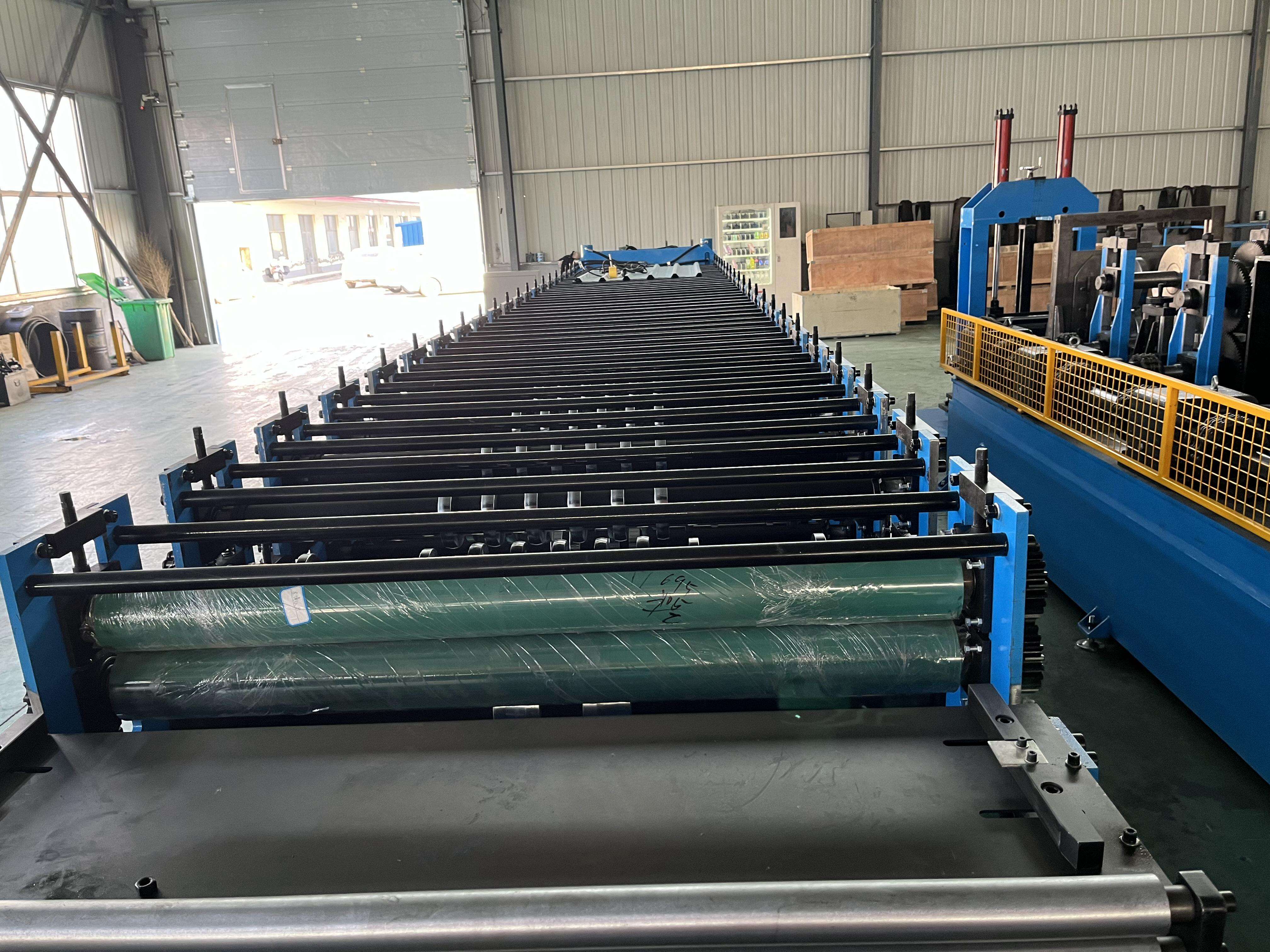

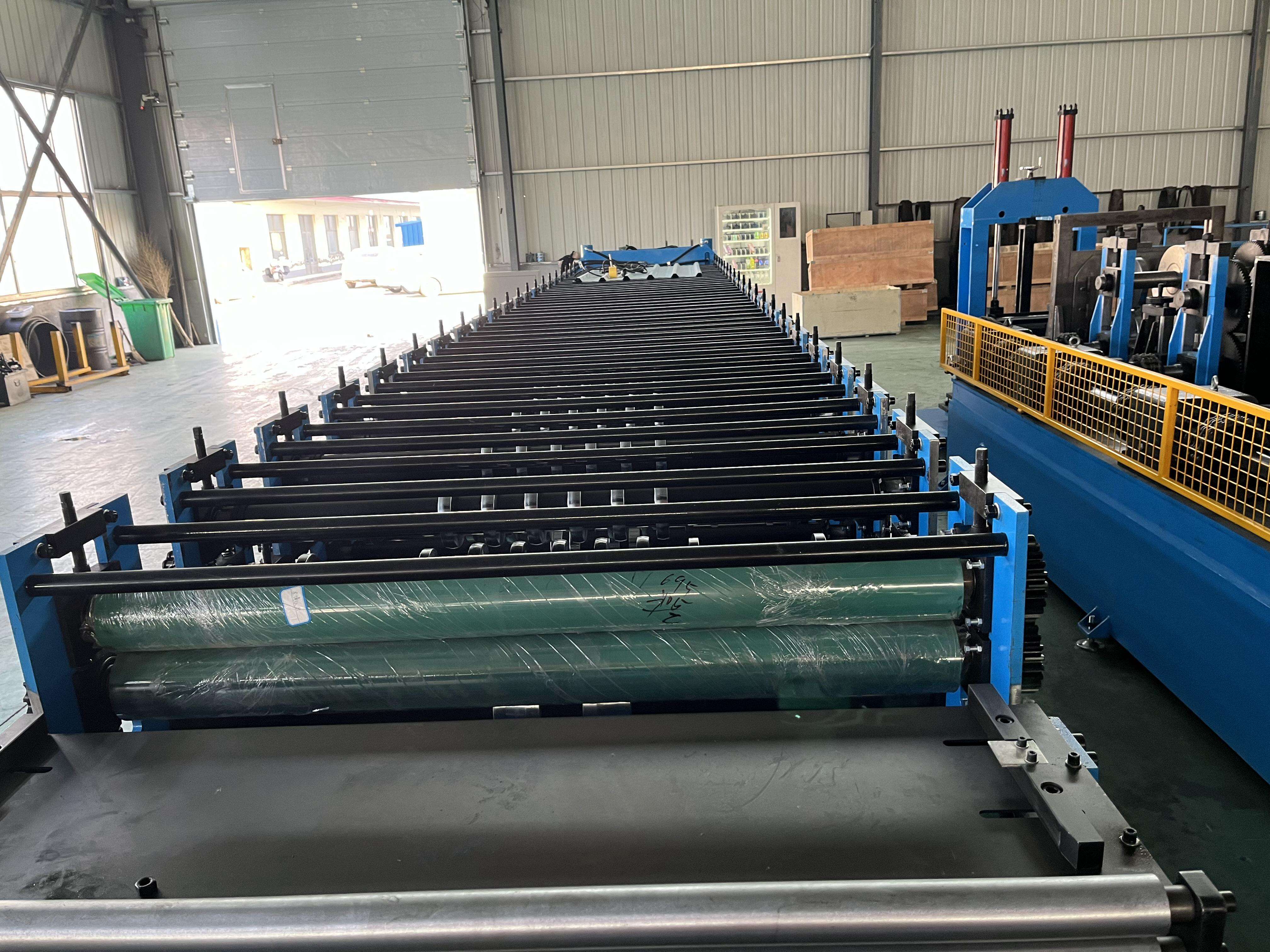

Roll forming part:

1. Material thickness range:0.3-0.8mm

2. Feeding width:according to the drawing

3. Effective width:according to the drawing

4. Speed:Upper layer is about 0-30m/min, lower layer is about 0-30m/min.

5. Quantity of rollers:18-20 rollers (according to the drawing)

6. Main motor power:7.5kw

7. Hydraulic station:4kw

8. Material of rollers:45# with chromed

9. Shaft Material and diameter:¢70mm, material is 45# forge steel

10.Size of machine:About 10m*1.5m*1.5m

11.Weight:About 10 tons

12. The body of machine:350H

13.Tolerance:10m+-1.5mm

14. Way Of Drive:Chain

15. Control system:PLC

16.Material of cutter blade:Cr12 mould steel with quenched treatment

58-62℃

17. Voltage:As customer’s requirements

Hydraulic cutter:

1. Cutting motion:The main machine automatically stops and then cutting.

After the cutting, the main machine will automatically start.

2. Material of blade:Cr12 mould steel with quenched

treatment58-62℃

3. Length measuring:Automatic length measuring

4. Tolerance of length:10+/- 1.5mm

Hydraulic station :

Product parameters table

| 5 tons manual Decoiler |

Max width of raw material:As customer’s requirements

Capacity:5000kgs

Inner diameter of coil:450-600mm

|

| Roll forming machine |

Material thickness range:0.3-0.8mm

Feeding width:according to the drawing

Effective width:according to the drawing

Speed:Upper layer is about 0-30m/min, lower layer is about 0-15m/min.

Quantity of rollers:18-20rollers (according to the drawing)

Main motor power:7.5kw

Hydraulic station:4kw

Material of rollers:45# with chromed

Shaft Material and diameter:¢70mm, material is 45# forge steel

Size of machine:About 10m*1.5m*1.5m

Weight:About 10 tons

The body of machine:350H

Tolerance:10m+-1.5mm

Way Of Drive:Chain

Control system:PLC

Material of cutter blade:Cr12 mould steel with quenched treatment 58-62℃

Voltage:As customer’s requirements

|

| Cutting

(hydraulic guide) |

Cutting motion:The main machine automatically stops and then cutting. After the cutting, the main machine will automatically start.

Material of blade:Cr12 mould steel with quenched

treatment58-62℃

.Length measuring:Automatic length measuring

Tolerance of length:10+/- 1.5mm

|

| PLC control system |

Voltage, Frequency, Phase:380V, 50Hz, 3Phase

Automatic length measurement

3Automatic quantity measurement

Computer used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved

Length inaccuracy can be amended easily

Control panel:Button-type switch and touch screen

Unit of length:Millimeter (switched on the control panel)

|

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY