Benefits of using a slitting line in metal processing

Although Slitting Line not a very tough process, it needs to be used with attention. The metal rolls are then set into the uncoiler, this device is for unwinding and processing. Then the metal is attached to a leveling tool that subsides it and prepares for cutting. Then the metal is shipped to slitter, where it generate in specified sizes. The cut strip is subsequently wound back on the re-coiler and so are they again ready for straightening.

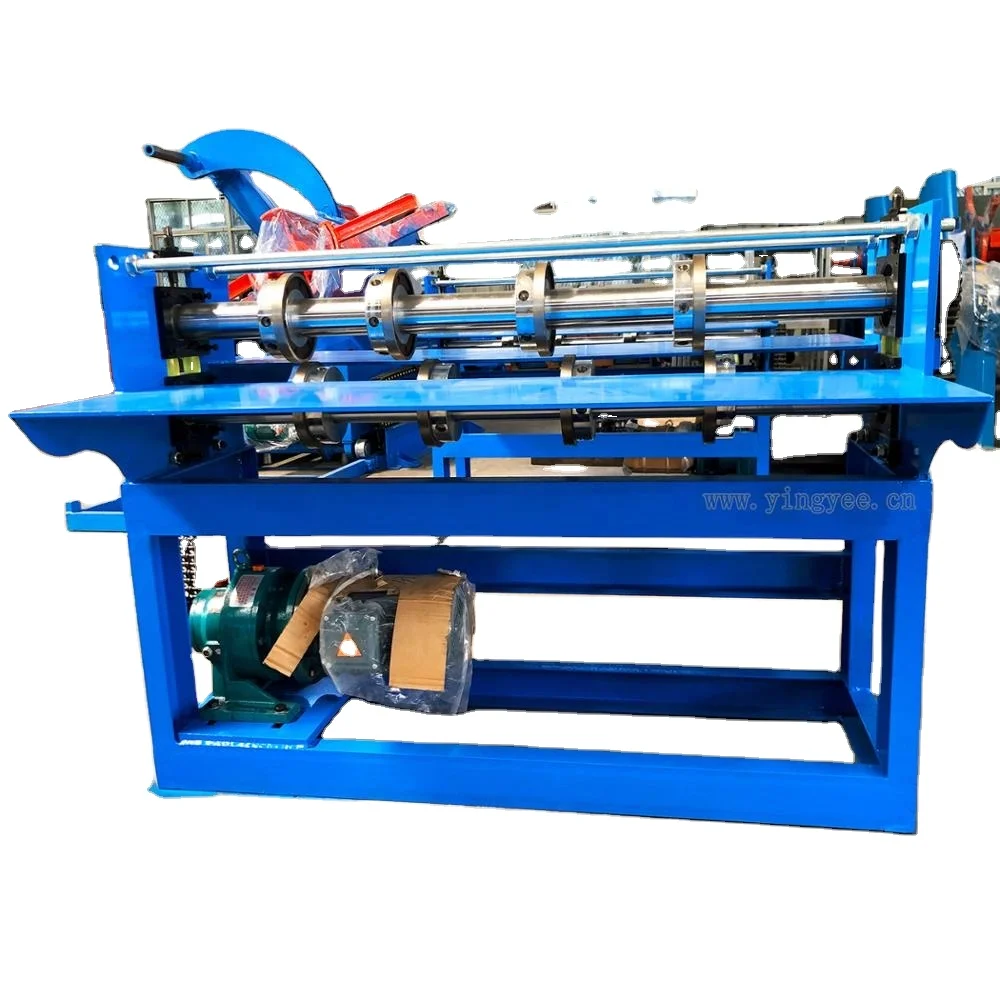

One of the key points to be taken care of in a slitting line so that it works perfectly when slit cylindrical products, such as rubber rings or tubes within the silicone, similar to the roll forming machine for sale built by YINGYEE. With the appropriate care, you would be able to maintain it longer by keeping an eye on cleanliness - Regularly cleaning dirt off surfaces that are not painted like lubricating or replacing parts if worn down from damage and wearing past its lifecycle. Operators need consider like manufacturers round the clock and keep in mind two major things, one being Longevity of Machine and another is functionality of machine.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY