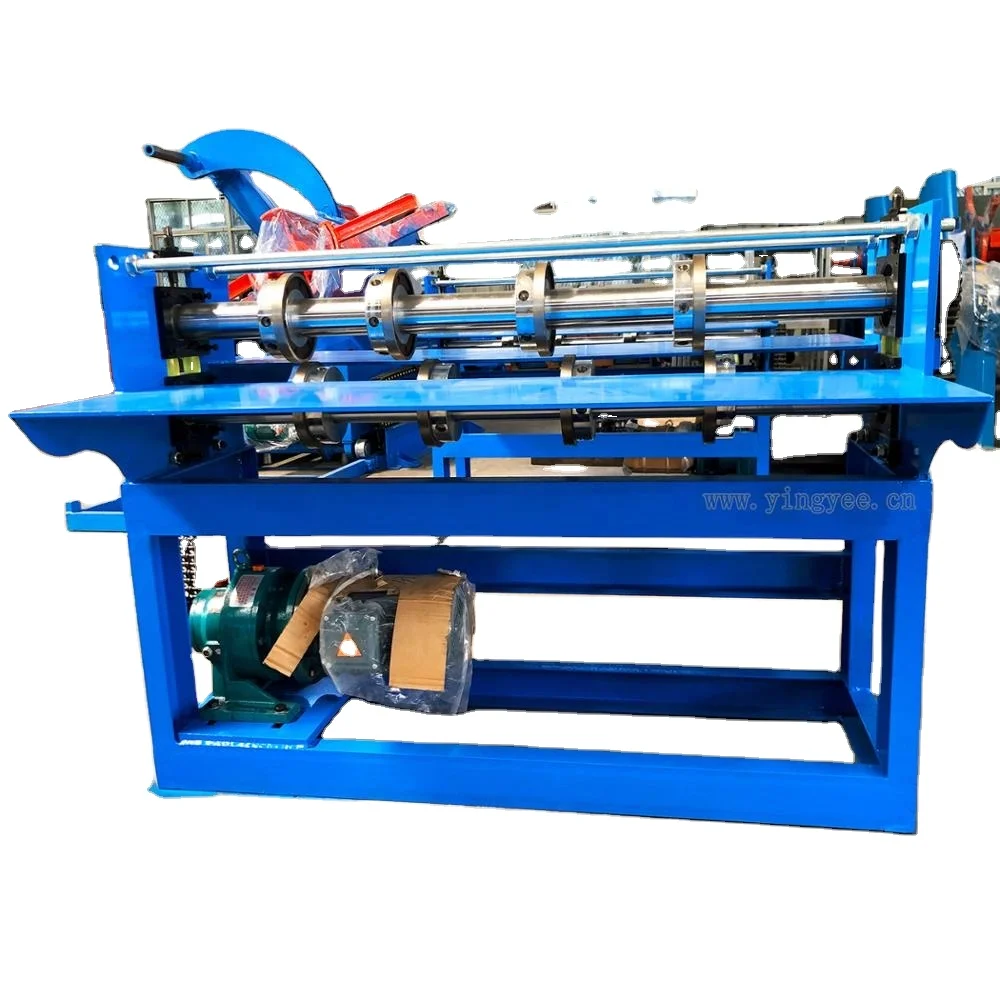

Customize Your Roofing Sheets with a Roll Forming Machine

From time to time, this way you home will look perfect and definitely be noticeable Roll forming machines help in creating roofing sheets which match the color, design and size you desire. It is a highly versatile machine that can shape the edges of any sheets in various forms. This uniqueness visual impact on your roof not only to blend with your style of the house, but it can match you as a person. Furthermore, the roll forming machine can even imprint patterns or designs on the sheets to make them more specific and aesthetic.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY