- COMPANY PROFILE

-

Products

- Roller shutter door roll forming machine

- Thread rolling machine

- Downpipe system roll forming machine

- Storage system production line

- Welded mesh machine

- Steel coil

- Decoiler

- Punching machine

- 3D laser cutting machine

- Automatic packing system

- Solar bracket roll forming machine

- Press break machine

- NC shearing machine

- Tube mill line

- Cut to length line

- Slitting line

- Straighten and cutting machine

- Drywall and ceiling system roll forming machine

- Purlin roll forming machine

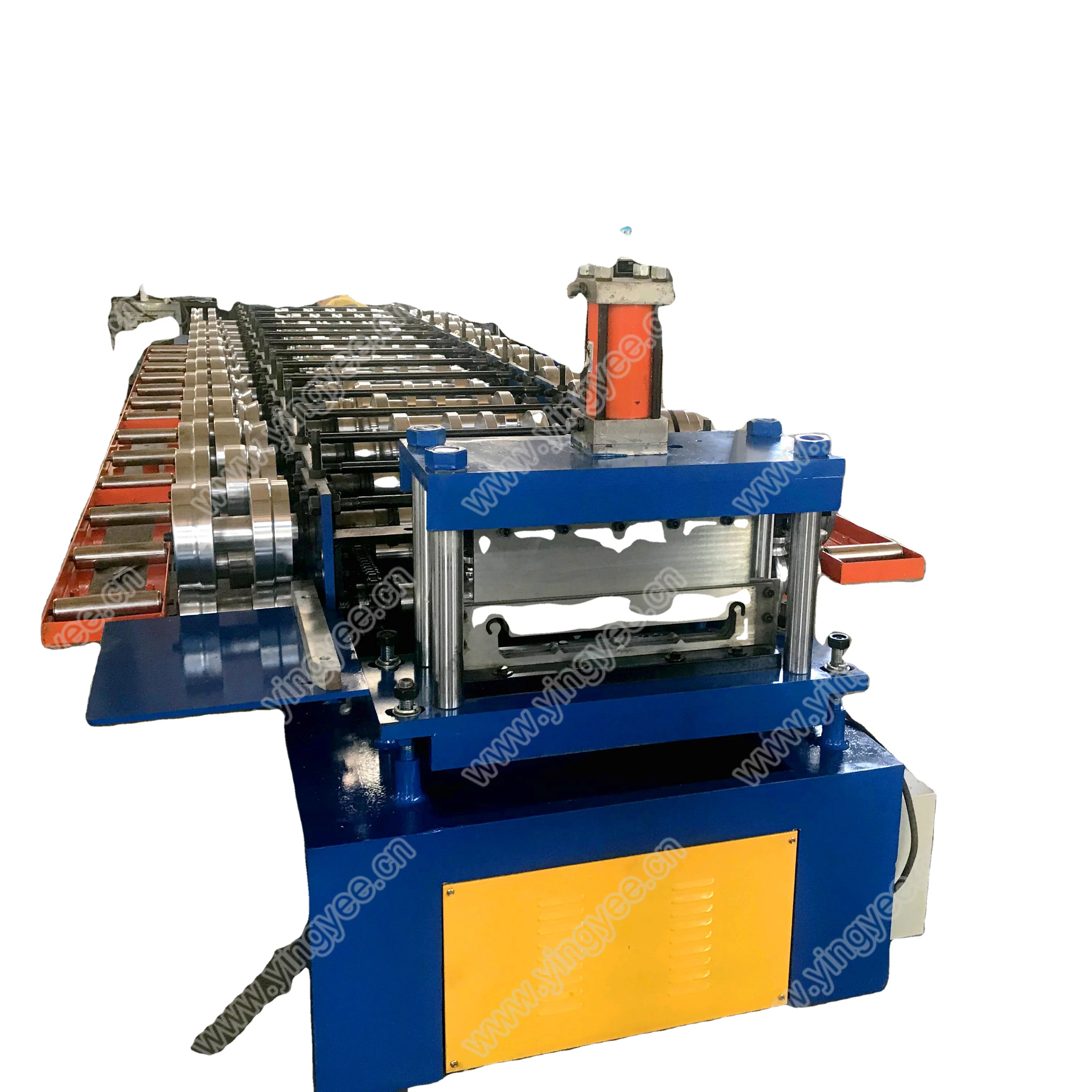

- Roof sheet roll forming machine

- Electrical cabinet production line

- NewsRoom

- Contact

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY