Roll Forming Machines: The Benefits of Rolling Streams

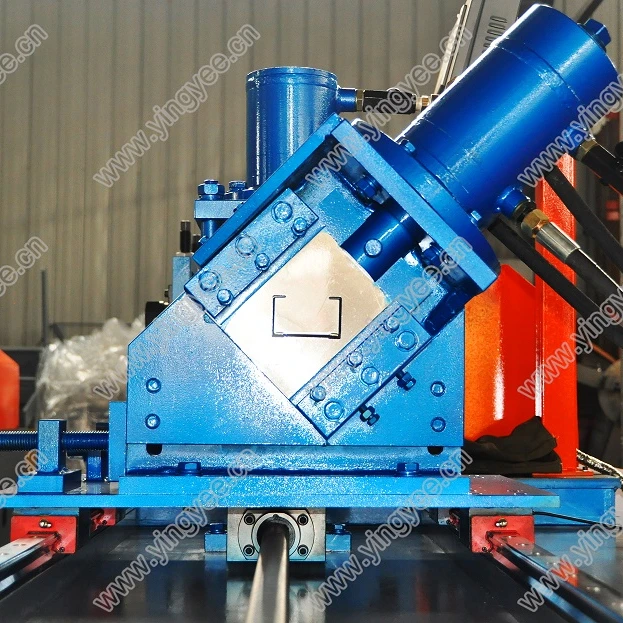

There are many advantages of the use of roll forming machines for purlin as follow. To begin with, these machines are more efficient as compared to the traditional methods because they supply a greater number of purlins in less time. This efficiency can also be beneficial for businesses with high volume purlin requirements within strict deadlines. Furthermore, the roll forming technique results in hard purlins that fit tightly to a roof spaced evenly. This accuracy is essential for avoid problems such as leaks and the collapse of structures.

Safety One of the more common advantages when it comes to roll forming machines is safety. Running these machines allows for there to be less injures as the machine does most of the work. The operation is as simple as loading metal into the machine and letting it shape your part. Which only improve efficiency and helps in creating a safe working atmosphere.

How to Choose a Best-fit Purlin Roll Forming Machine for Business

Selecting the perfect roll forming machine for your business is not a choice that ought to be made lightly. Whether or not the chosen machine fits with what you need, there are a number of other factors to bear in mind when looking for this refrigerating thing. The first thing to think about is what size you wish the purlins that are produced thus knowing which machine has been set up for different sizes. Moreover, the kind of metal that you intend to use will have to be compatible with the unit chosen. Make Sure a Machine Operates on the Type of Metal You Want to Use Finally, affects of financials should not be missed. Although roll forming machines can be costly, it is imperative to choose one that will remain within your budget. Although, one must remember that higher capital to invest in the more sophisticated machines at first might bring high efficiency and lower running costs.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY